A capacitor is an electrical component used to store energy in an electric field. It has two electrical conductors separated by a dielectric material that both accumulate charge when connected to a power source. One plate gets a negative charge, and the other gets a positive charge.

A capacitor does not dissipate energy, unlike a resistor. Its capacitance characterizes an ideal capacitor. It is the amount of electric charge on each conductor and the potential difference between them. A capacitor disconnects current in DC and short circuits in AC circuits. The closer the two conductors are and the larger their surface area, the greater its capacitance.

COMMON TYPES OF CAPACITORS

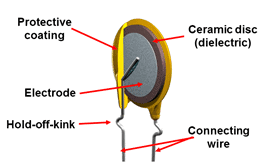

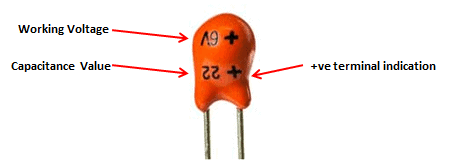

Ceramic disc capacitors use ceramic for the dielectric material. A ceramic capacitor is encapsulated with two leads that emanate from the bottom then form a disc. A ceramic disc capacitor does not have a polarity and connects in any direction on the printed circuit board. In ceramic capacitors, a relatively high capacitance is achievable in a small physical size because of its high dielectric constant. Its value ranges from picofarad to one or two microfarads, but its voltage ratings are relatively low.

The three-digit code printed on their body is used to identify the capacitor’s value in the picofarad. Letter codes are used to indicate their tolerance value such as the following: J = 5%, K = 10% or M = 20%. For example, the ceramic disc capacitor above with a marking of 154 indicates that there are 15 and 4 zero’s of picofarad, or 150,000 pF (150nF).

Tolerance Value of Ceramic Disc Capacitor

Electrolytic capacitors are often used when large capacitance values are needed. They are commonly used to help reduce ripple voltages or for coupling and decoupling applications. Electrolytic capacitors are constructed using two thin films of aluminum foil with an oxide layer as an insulator. They are polarized, and can be damaged or explode when connected incorrectly. This type of capacitor has a wide tolerance but does not operate well at high frequencies.

|

| Electrolytic capacitors |

Tantalum capacitors are commonly used for medium range levels of capacitance. They are best used when the size and performance matters, but they do not usually have high working voltages and don’t have very high current capacity. Tantalum capacitors are polarized and can explode when placed under stress. They have a very low tolerance for being reverse-biased.

The markings on SMD tantalum capacitors usually consist of three numbers. The last one is the multiplier, and the first two are significant figures. Its values are in picofarads. Therefore, the SMD tantalum capacitor shown above has a value of 47 x 106 pF, which works out as 47µF.

Tantalum capacitors can also be marked directly as shown in the figure above.

Silver mica capacitors are used for many RF circuits like oscillators and filters. Silver mica gives a very high-level performance with close tolerance values but small change in terms of temperature. It uses silver electrodes that are plated directly onto the mica. Several layers help in gaining the required level of capacitance and this capacitance is affected by the area covered by the electrodes.

Film capacitors use a thin plastic film as the dielectric. Film capacitors are used in many applications because of their stability, low inductance, and low cost. They are not polarized, so they’re suitable for AC signal and power use. They are also made with very high precision capacitance values and retain it longer than any other type of capacitor.

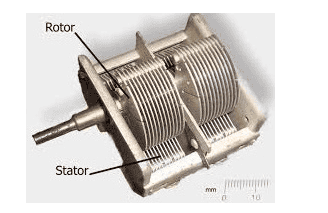

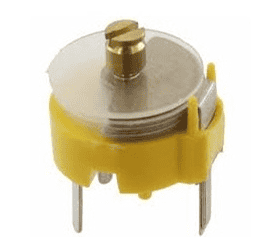

Variable capacitors are capacitors with a capacitance that can be varied based on the requirement to a specific range of values. Variable capacitors consist of plates made of metal. Among these plates, one is fixed while the other is movable. Thier capacitance can range from around 10 picofarads to 500 picofarads. There are a lot of uses for these variable resistors, such as tuning LC circuits in radio receivers, for impedance matching in antennas, etc. There are two types of variable capacitors—tuning capacitor and trimmer capacitor.

The frame in this capacitor provides support to the capacitor made of mica and the ‘stator’ present in it. With the help of the shaft, the rotor tends to rotate while the stator is stationary. Once the plates of the movable rotor enter into the fixed stator, the capacitance is possibly at the maximum level. Otherwise, the value of the capacitance is at the minimum.

This type of capacitor has three leads. One is connected to the stationary part, the other to the part that is responsible for the movement called rotary and the other lead is common.

POLARIZED VS NON-POLARIZED CAPACITORS

When it comes to storing and discharging, both of them have the same principle. However, there are a lot of factors that make them different from each other.

Different dielectrics – Dielectric is the material between the two capacitor plates. Polarized capacitors use an electrolyte as the dielectric giving them a larger capacitance than other capacitors of the same volume. However, polar capacitors produced by different electrolyte materials and processes will have different values of capacitance. The use of polar and non-polarized capacitors depends on the properties of the dielectric that are reversible.

Different structures – the most commonly used electrolytic capacitors are round; square capacitors are rare. There are also invisible capacitors, or distributed capacitors, which must not be ignored in high frequency and intermediate frequency devices.

Use environment and usage – internal materials and structures provide for the large capacity and high-frequency characteristics of polar capacitors that make them very suitable for power supply filters and the like. However, there are some polar capacitors with good high-frequency characteristics— tantalum electrolysis, which is not commonly used because of its high cost.

Different performance – Maximum performance is one of the main requirements in choosing a capacitor. If a television’s power supply is using a metal oxide film capacitor as a filter, the capacitance and withstanding voltage should meet the filter requirements; only a power supply can be installed inside the case. Therefore, the filter can only use polar capacitors, and the polar capacitance is irreversible. Usually, electrolytic capacitors are above 1 MF; best used in coupling, decoupling, power supply filtering, etc. Non-polar capacitors are mostly below 1 MF, which only involves resonance, coupling, frequency selection, current limiting, etc. However, there are also large-capacity, high-voltage non-polar capacitors, mainly used for reactive power compensation, motor phase shift, and frequency conversion power phase shift.

Different capacity – capacitors that have the same volume have different capacitances depending on their dielectrics.

COMMON USES OF CAPACITORS

AC coupling/DC blocking – the component allows only AC signals to pass from one section of a circuit to another while blocking any DC static voltage. They are commonly used to separate the AC and DC components of a signal. In this method, it is necessary to ensure that the impedance of the capacitor is sufficiently low. The capacitor rated voltage must be greater than the peak voltage across the capacitor. Usually, the capacitor will be able to withstand the supply rail voltage with some margin to ensure reliability.

Power supply decoupling – The capacitor is used to decouple one part of a circuit from another. Decoupling is done when an incoming line signal is taken through a transformer and a rectifier; the resulting waveform is not smooth. It varies between zero and the peak voltage. If applied to a circuit, this is most unlikely to operate because a DC voltage is typically needed.

Filter AC noise from DC circuits – Any AC signals that may be on a DC bias point, power rail, or other nodes that need to be free of a particular varying signal should be removed by the capacitor. It must also be able to withstand the supply voltage while supplying and absorbing the levels of current arising from the noise on the rail.

Audio signal filtering – it is necessary to consider the capacitor’s RF performance. This performance can be different at lower frequencies. Ceramic capacitors are usually used here since they have a high self-resonant frequency, specifically the surface mount capacitors that are very small and have no leads that can cause any inductance.

WHAT ARE SUPERCAPACITORS?

It is also known as a double-layer electrolytic capacitor or ultracapacitor. A supercapacitor can store a large amount of energy. Specifically, 10 to 100 times more energy per unit mass or volume compared to electrolytic capacitors. It has lower voltage limits that bridge the gap between electrolytic capacitors and rechargeable batteries.

SOME COMMON USES OF SUPERCAPACITORS

Wind turbines – supercapacitors help to smooth out the intermittent power supplied by the wind.

Motors – that drive electric vehicles run off power supplies rated in the hundreds of volts, which means hundreds of supercapacitors connected in series are needed to store the right amount of energy in a typical regenerative brake.

Electric and hybrid vehicles – supercapacitors are used as temporary energy stores for regenerative braking, where the energy of a vehicle would generally go to waste when it comes to a stop, briefly stored and then reused when it starts moving again.

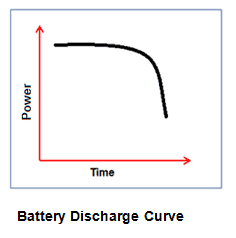

SUPERCAPACITORS AND BATTERY DISCHARGE CURVE

The discharge curve of the battery is exponential. As you can see, exponential discharge provides steady power to the end. The energy stays high during most of the charge and then drops rapidly as the charge depletes.

The discharge curve of the supercapacitor is linear. As you can see, linear discharge prevents the full use of energy. It delivers the highest power at the beginning.